Liquid Stock Control

A total of seven measurements, four liquids, one powder, one powder in liquid(Brine), and an oil water mix all needed to be monitored in one central place. The top surface of the liquids were detected by use of an ultrasonic emitter and detector and the position of the surface converted to volume of liquid and graphically displayed on a monitor.

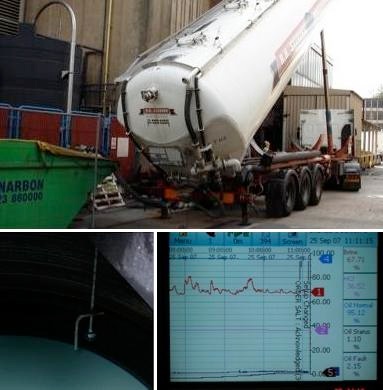

The surface of the salt was measured by an ultrasonic probe under the surface of the brine this was then converted to mass of salt and graphically displayed on the monitor. The old method of detecting the surface used a weight on a string that can be seen on the left hand side of the photo. The weight was buried and so useless.

The waste oil tank consisted of a tank initially filled with water which was displaced by the oil, the water flowing out of an overflow, until it was almost full of oil. This point was detected ultrasonically for the tank to be emptied of the oil. The full point is indicated on the monitor.

Finally the silo containing bicarbonate was monitored in a completely different way. Knowing the initial mass of the bicarbonate the rate of usage was measured by knowing the pump performance and the speed of the pumps. These were integrated and then subtracted from the initial quantity, giving a new mass in stock.

This complete system was designed and built by Erlebach Engineering Ltd